Hospital Laundry

Achieve quantifiable cleanliness.

Know your industry

The hospital industry in India is estimated to grow to ₹ 8,60,000 crores (USD 132.8 billion) by FY22 (Fiscal Year) from ₹ 4,00,00 crores (USD 61.8 billion) in FY17. By 2020, the Indian medical tourism industry is likely to be valued at about ₹ 62,055 crores (USD 9 billion).

(Source: IBEF)

Problems faced by Hospital Laundries

1. Achieving quantifiable hygiene

Cleanliness now-a-days is quantifiable and can be achieved using the Barrier Laundry Concept.

2. Increasing operational costs

Manpower, raw material, logistics, real estate and utility costs are increasing every year.

3. Very limited adoption of latest technology

Hospital management has very limited awareness of financial benefits delivered by latest machines.

4. Shortage of manpower

It is a labor-intensive business and there is a shortage in of competent manpower in India.

5. Lack of well defined laundry-hygiene processes

There is a shortage of well defined SOPs – Standard Operating Processes to optimize the day-to-day operations and prevent cross-contamination.

Why QUICKCLEAN??

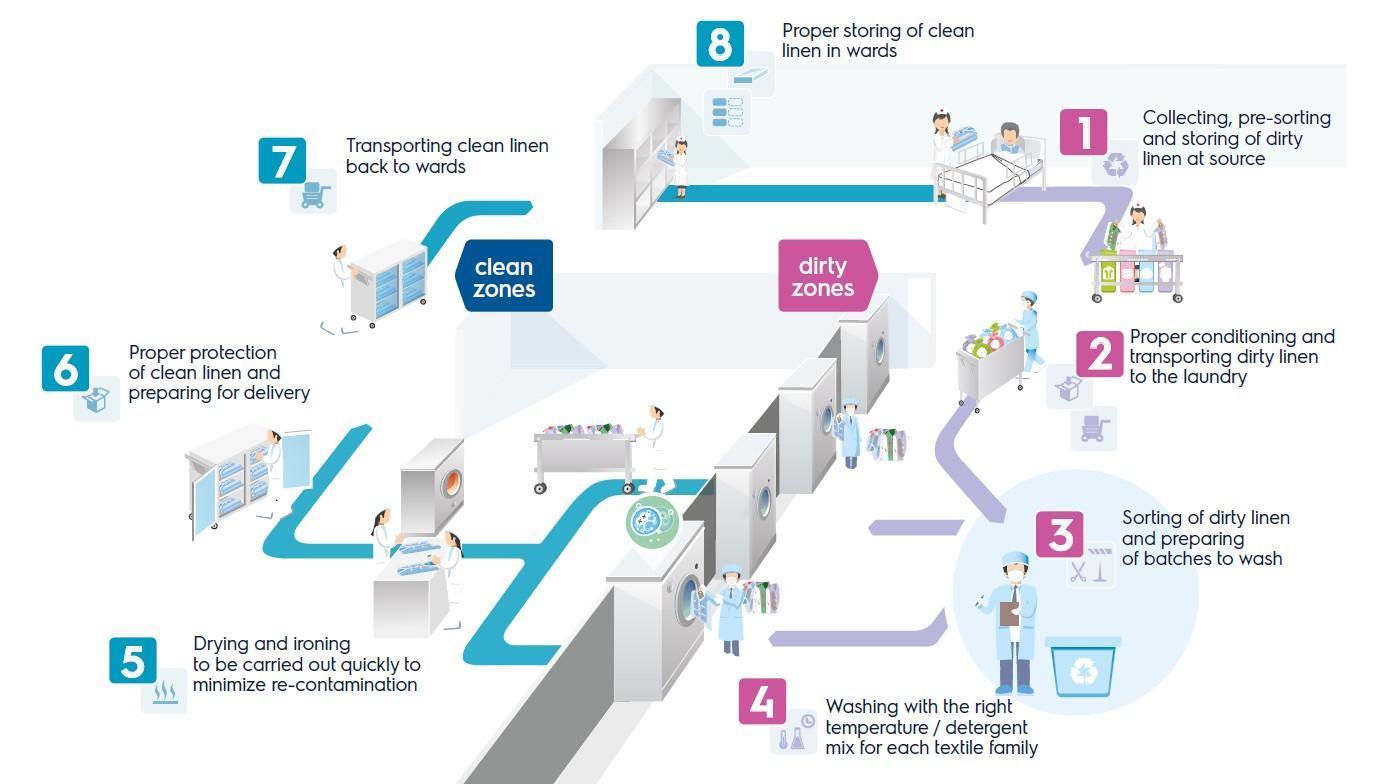

For QUICKCLEAN it is not just a laundry but management of a complete cycle that begins with at a dirty bed and ends at a clean bed.

1. Define and Implement a process

QUICKCLEAN recommends the barrier concept, a functional separation of soiled and clean linen, in which dirty linen enters from one side and clean linen exists via another side. This eliminates any chances of contamination even by human error. The barrier concept conforms to the EN 14065: Risk Analysis and Bio-Contamination Control.

2. Supply and install specialized laundry equipment

Elimination, destruction and inhibition of micro-organisms can be achieved through the application of, heat above 65°C, detergents with pH above 12, minimum wash-time and particular mechanical action. The synchronization of all these variables synched is called “Sinners Cycle” – it is known to achieve optimum washing quality. Electrolux Barrier Washers have wash programs created that conform to the “Sinners Cycle” logic.

The automatic savings feature in the washers reduces water and energy consumption and the hygiene watchdog feature ensures prevents unloading on the clean side unless disinfection is achieved.

3. Training

Hospital laundry is a life and money saving cycle that begins from a dirty bed and ends at clean bed. Based on the innovative barrier approach QUICKCLEAN will chalk out all the steps in the cycle. So, that it can provide the precise training to perform each step and entire process efficiently.

4. Help to focus on core operation

With QUICKCLEAN’s, BOO – Build, Own and Operate Model you wash away all your existing problems, to extract the highest quality of output and maximize savings. The biggest advantage of this model is free upgrade of your legacy equipment with the latest Electrolux appliances. Also, you can leverage our experience, to optimize your processes and offer other value added services.

5. Implement an auditing and reporting system

QUICKCLEAN empowers you to exercise more control over your facility by capturing machine data via the information system. The information system not only provides you an accurate and up-to-date dashboard of your facility also offers insights to enhance productivity and reduce costs.

Laundry Linen Flow

An efficient care solution for you. A comfortable lifestyle for patients and guests.

Recommended Products

W5250S

Rigid frame, drum volume 250L, G-factor 200, with programmable microprocessor Compass Pro®

- Four compartment detergent box for manual dosing of powder or liquid detergent.

- Extremely low water and energy consumption.

- High extraction force for efficient dewatering.

- Door with gasket and strong hinges built for heavy duty operation.

WB5130H

Suspended frame, drum volume 130L, G-factor 300, front loaded barrier washer extractor with programmable Compass Pro microprocessor

- Maximises the extraction force, leading to highest dewatering and savings in drying.

- Minimizes the stress on the machine, leading to trouble-free operation and increased machine lifetime.

- Reduces vibrations, making it possible to install the machine in all locations.

WB5180H

Suspended frame, drum volume 180L, G-factor 300, front loaded barrier washer extractor with programmable Compass Pro microprocessor

- Has a flexible, customisable and user friendly interface.

- Makes operators’ life easier allowing them to have up to 55 programs available of which 15 are programmable.

- Compatible with up to 16 detergent signals as a standard to withstand the most complicated programs.

WHB5500H

Hyvolution barrier washer, drum volume 500L, with Compass Pro®

- Two compartment inner drum separated by a Pullman partition for the best ergonomics and mechanical action of the market.

- Large inner drum doors to make loading and unloading operation easiest than ever.

- Feature the Power Balance from Electrolux that ensures the best extraction whatever the loading conditions are.

WPB41100H

Suspended frame, drum volume 1080L, G-factor 300, side loaded pullman barrier washer extractor with fully programmable Clarus TS microprocessor

- 5 compartment soap box for manual supply or connection to automatic liquid system.

- Two compartment inner drum separated by a Pullman partition for the best ergonomics and mechanical action of the market.

- Automatic inner drum positioning in loading or unloading position.

WPB4700H

Suspended frame, drum volume 690L, G-factor 300, side loaded pullman barrier washer extractor with fully programmable Clarus TS microprocessor

- 5 compartment soap box for manual supply or connection to automatic liquid system.

- Two compartment inner drum separated by a Pullman partition for the best ergonomics and mechanical action of the market.

- Automatic inner drum positioning in loading or unloading position.

WPB4900H

Suspended frame, drum volume 890L, G-factor 300, side loaded pullman barrier washer extractor with fully programmable Clarus TS microprocessor

- 5 compartment soap box for manual supply or connection to automatic liquid system.

- Two compartment inner drum separated by a Pullman partition for the best ergonomics and mechanical action of the market.

- Automatic inner drum positioning in loading or unloading position.

WSB5200H

Barrier Washer Extractor WSB5200H, drum volume 200L, with electrical heating, Compass Pro®, 2 doors, right load/right unload

- Pass-through construction to offer the best ergonomics in barrier installations.

- Compass Pro® controller with a user friendly interface to make the operator’s life easy allowing 40 factory and 15 customised wash programs.

- Large inner drum doors to make loading and unloading operation easiest than ever.

WSB5270H

Barrier Washer Extractor WSB5270H, drum volume 270L, with electrical heating, Compass Pro®, 2 doors, right load/right unload

- Pass-through construction to offer the best ergonomics in barrier installations.

- Compass Pro® controller with a user friendly interface to make the operator’s life easy allowing 40 factory and 15 customised wash programs.

- Large inner drum doors to make loading and unloading operation easiest than ever.

WSB5350H

Suspended frame, drum volume 350L, G-factor 350, side loaded barrier washer extractor with fully programmable Compass Pro microprocessor.

- Pass-through construction to offer the best ergonomics in barrier installations.

- Compass Pro® controller with a user friendly interface to make the operator’s life easy allowing 40 factory and 15 customised wash programs.

- Large inner drum doors to make loading and unloading operation easiest than ever.

T41200

1200L, tumble dryer with Selecta microprocessor

- Easy access to vital parts from the top and rear for simple servicing.

- High productivity – 2 full loads per hour.

- Selection of temperature and time for easy operation.

- Large door opening for easy loading/unloading.

T4900

900L, tumble dryer with Selecta microprocessor

- Easy access to vital parts from the top and rear for simple servicing.

- High productivity – 2 full loads per hour.

- Selection of temperature and time for easy operation.

- Large door opening for easy loading/unloading.

T5290

290L, tumble dryer with programmable Compass Pro® microprocessor

- High productivity – 2 full loads per hour.

- Large door opening for easy loading/unloading.

- Axial airflow and tight construction gives low energy consumption.

- The coin version with Ecopower to avoid over drying of the garments and get a lower energy consumption.

T5550

550L, tumble dryer with Compass Pro® microprocessor

- High productivity – 2 full loads per hour.

- Large door opening for easy loading/unloading.

- Axial airflow and tight construction gives low energy consumption.

- The coin version with Ecopower to avoid over drying of the garments and get a lower energy consumption.

T5675

675L, tumble dryer with Compass Pro® microprocessor

- High productivity – 2 full loads per hour.

- Large door opening for easy loading/unloading.

- Axial airflow and tight construction gives low energy consumption.

- The coin version with Ecopower to avoid over drying of the garments and get a lower energy consumption.

C-Flex 930.1

Chest type ironer, 1 roll, average linen output 370 kg/h

- Chest type industrial ironer with mobile chest and fixed roll, offering a constant pressure and a maximum ironing surface for the utmost ironing quality.

- Steam or thermal oil heating.

- The unique design of the chest and roll combined with an improved thermal insulation give a thermal output close to 97%.

- Up to three chest can be mounted together for a 50m/min maximum ironing speed.

IB5730

Flexible chest ironer with 700 diam. cylinder and 3000 length

- One-person operation from feeding wet items to piles of folded sheets – The optimum in ironing (only for IC44819 FFS, IC44825 FFS, IC44832 FFS).

- One station automatic feeding with electro-mechanical clamps and standard vacuum table for a smooth and efficient quality feeding (only for IC44819 FFS, IC44825 FFS, IC44832 FFS).

- Standard touch screen control with text free operating mode for optimum user friendliness (only for IC44819 FFS, IC44825 FFS, IC44832 FFS).

IC43320

Cylinder type ironer, 2065mm working width

- Finger guard protection provides additional safety for operators.

- Durable ironing belts of Nomex® withstand temperatures above 200°C.

- Easy to use control panel.

- Ergonomic working height.

IC44819

Cylinder type ironer, 1910mm working width with feeding, folding and stacking

- Finger guard protection provides additional safety for operators.

- Fully electric feeder requiring no compressed air while guaranteeing regular, silent and smooth work.

- Electro-mechanical clamps, automatic linen detection, smooth closing and holding of the linen, smooth opening and feeding of item (compensation of the elasticity of the fibres).

IC44821

Cylinder type ironer, 2120mm working width

- Finger guard protection provides additional safety for operators.

- Nickel-plated cylinder prevents rust and improves life-time.

- Easy access to all parts for easy maintenance.

- Maintenance free ceramic gas burner minimizes downtimes. 20% more efficient than regular blue flame burners. A unique and patented burner by Electrolux.

C-Flex 930.1

Chest type ironer, 1 roll, average linen output 370 kg/h

- Chest type industrial ironer with mobile chest and fixed roll, offering a constant pressure and a maximum ironing surface for the utmost ironing quality.

- Steam or thermal oil heating.

- The unique design of the chest and roll combined with an improved thermal insulation give a thermal output close to 97%.

- Up to three chest can be mounted together for a 50m/min maximum ironing speed.

Mini Spotty

- Stainless steel surface.

- Powerful suction, operated by foot pedal.

- Two spotting guns equipped with tanks for chemicals.

Geyser 16L

Electric steam generators with 16 litres boiler and modular heating elements. Available in 12 KW or 15 KW size.

Geyser 26L

Electric steam generators with 26 litres boiler and modular heating elements. Available from 18 KW to 30 KW size.

H series for laundry

Range of laundry presses.

- Hand guard.

- Pressing strength adjustment.

- Repositionable pedal.

Heater

- Suitable for indoor and outdoor use.

- Supports natural or propane gas.

- Can be used a secondary heat source for solar hot water delivery system.

50 KG GAS BOILER

- Our first product introduced into the Indian market was a 50 KG gas-based boiler to generate steam. One of the first of its kind in India.

Vacuum Iron Table

- Identifying the need for a large surface area for ironing. QUICKCLEAN developed a unique vacuum table, which has the biggest surface area, 5 x 2 feet, as compared to any other ironing table available in the Indian market. The larger area significantly boosts productivity of the operator.

For a detailed cost-benefit analysis or to visit our experience center please contact our expert laundry specialist

Testimonials

Our Clients